Sustainable energy future: BGH Edelstahl focusses on green electricity

It is impressive to see how BGH promotes the use of electricity from renewable energy sources such as solar or wind in its operations.

Stainless steels, tool steels as well as nickel and special alloys made in Germany, with diameters from less than a tenth of a millimetre to over a metre - that is our speciality!

For more than 550 years, tradition, innovation, flexibility and customer proximity have been the basis of our production and satisfied customers.

In 2022, we joined Science Based Targets and have committed us to a scientifically based climate target to reduce our CO2 emissions by 42% until 2030 and to achieve climate neutrality in the long term. In this way, we are consistently pursuing our annual energy savings targets, which were first set in 2012.

Thanks to a high investment rate, BGH has one of the most modern plant structures in the world. Innovations such as fully automated ultrasonic testing facilities for bar steel up to 1 000 mm in diameter or induction heat treatment lines are just a few examples.

With our fully integrated production process - from the melt to the finished wire, bar or open-die forging - we guarantee product quality for the highest demands.

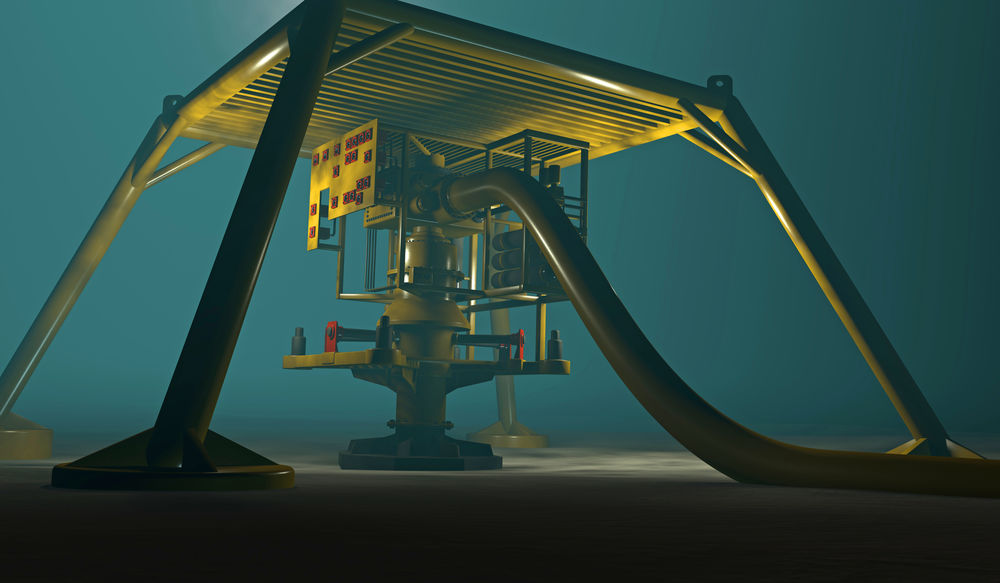

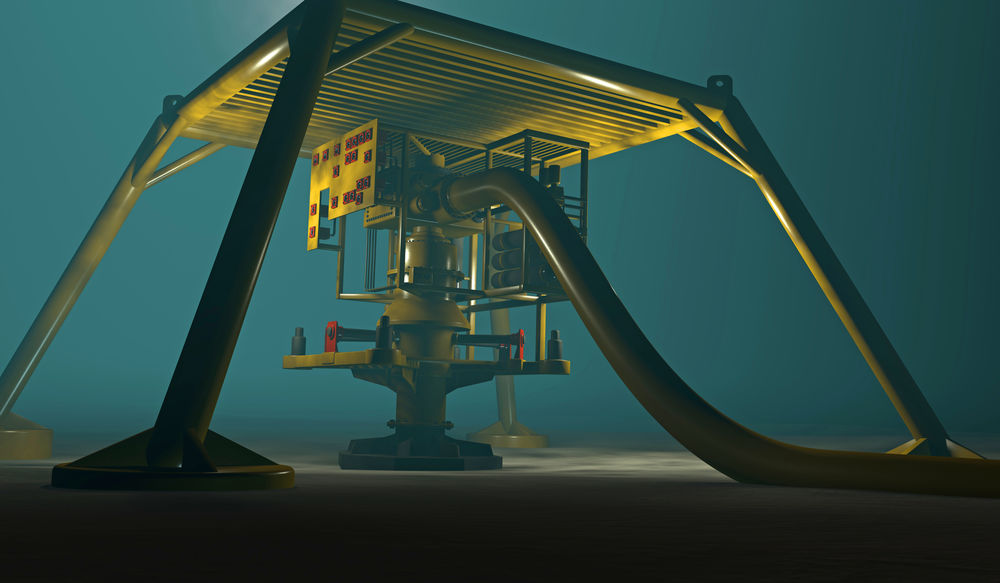

Whether corrosion-, heat- or wear-resistant: Our stainless steels and special alloys enable advanced developments in areas such as sustainable energy production, mobility, engineering, medical or environmental technology and stand for quality and reliability.

Our service centres offer a broad bar stock range of more than 70 materials, with fast service, worldwide availability and solutions even for your complex procurement tasks.

All our sites are certified to ISO 9001, ISO 14001 and ISO 50001. In addition, we meet extensive industry and customer approvals and hold other site-specific certificates such as IATF 16949 or ISO 17025.

BGH Edelstahl in a nutshell

Founded 1466

Owner-operated

2 200 Employees

700 m € turnover (2021)

165 000 t Sales, of which approx. 55 % in Germany

9 % remelted grades (ESR/PESR/VAR)

6 Production sites

9 BGH Steel Service Centers and and further sales partners worldwide

Your forging tool fails because of cracks? Your extrusion or die-casting process requires toughness on the level of ESU grades, but they are too expensive? The service life of your cutting tools is too low and PM steels are not an alternative?

Then our BGH One grades are the right choice for you! Through optimised alloy concepts, we surpass the properties of standard materials and offer you solutions away from expensive ESU and PM steels.

Contact us and convince yourself of the advantages of our innovative premium hot and cold work steels DieCast One, Tough One, Press One and Cut One.

Our delivery program ranges from fine wire with a diameter of 0.08 mm to rods in round, flat and square dimensions to forged products with a weight of up to 30 t and diameters of 2 m.

In combination with over 300 materials manufactured by us, this results in a unique product spectrum for our customers - all from one source!

For more details check our delivery program or contact us!

a selection

It is impressive to see how BGH promotes the use of electricity from renewable energy sources such as solar or wind in its operations.

Endlich ist es soweit. Das Lieferprogramm und Angebot der Stahl-Servicecenter BGH SL-Stahl und BGH Specialstahl Süd ist jetzt auch als Broschüre erhältlich!